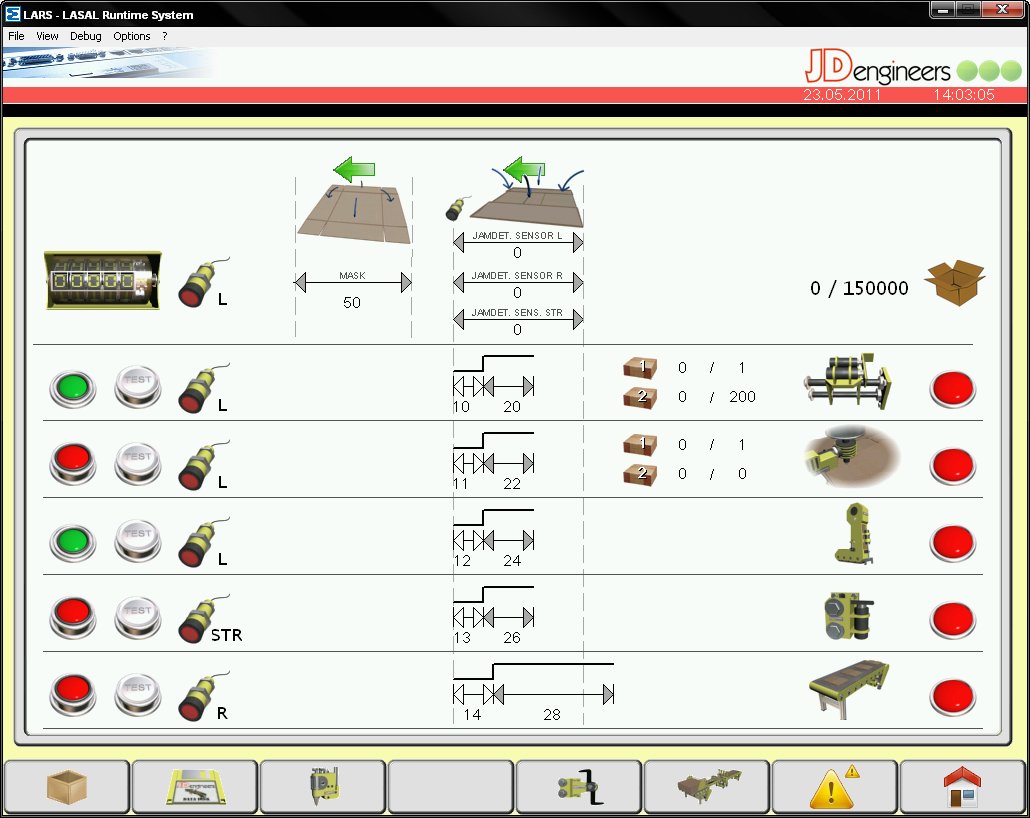

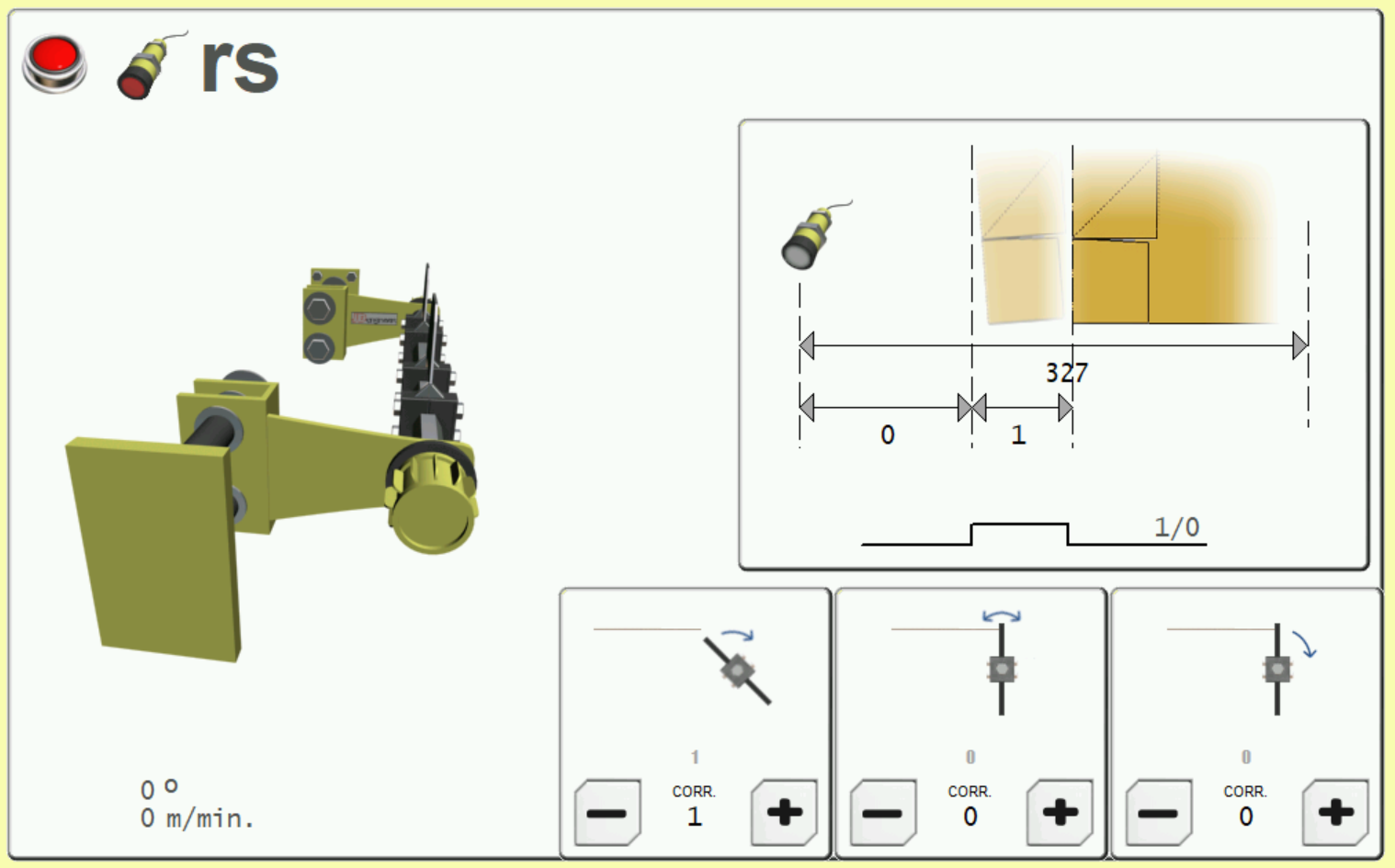

Jam detect

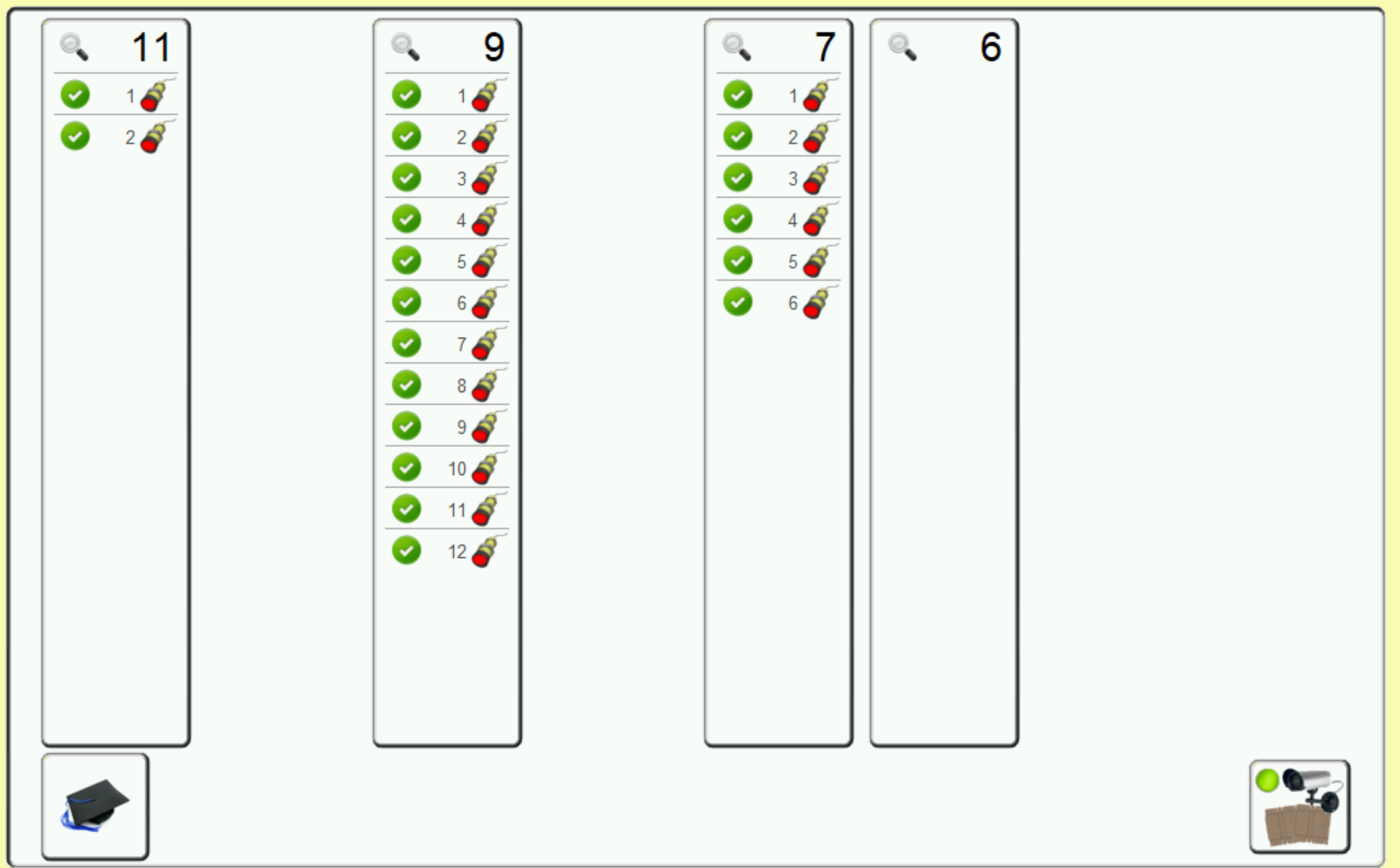

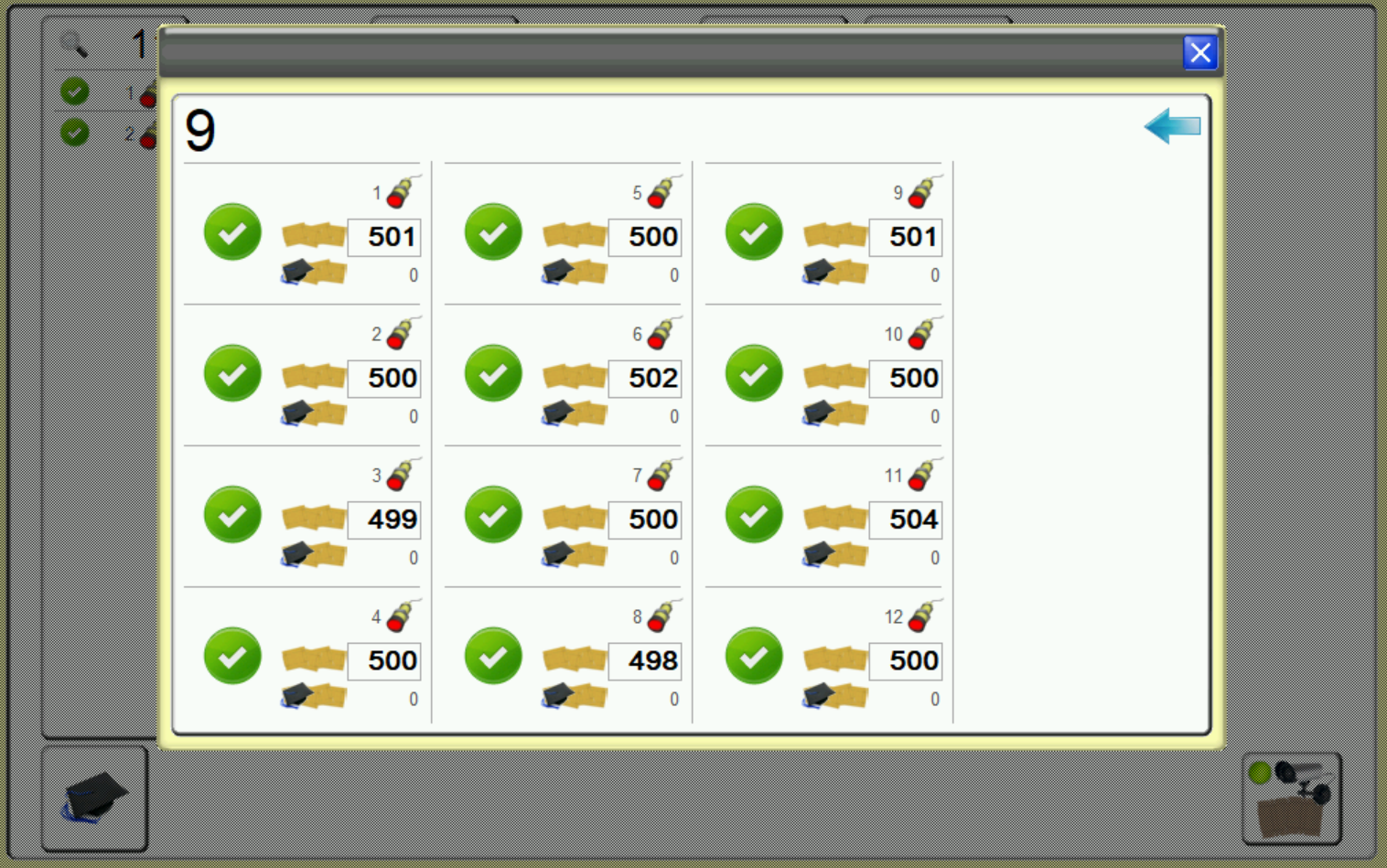

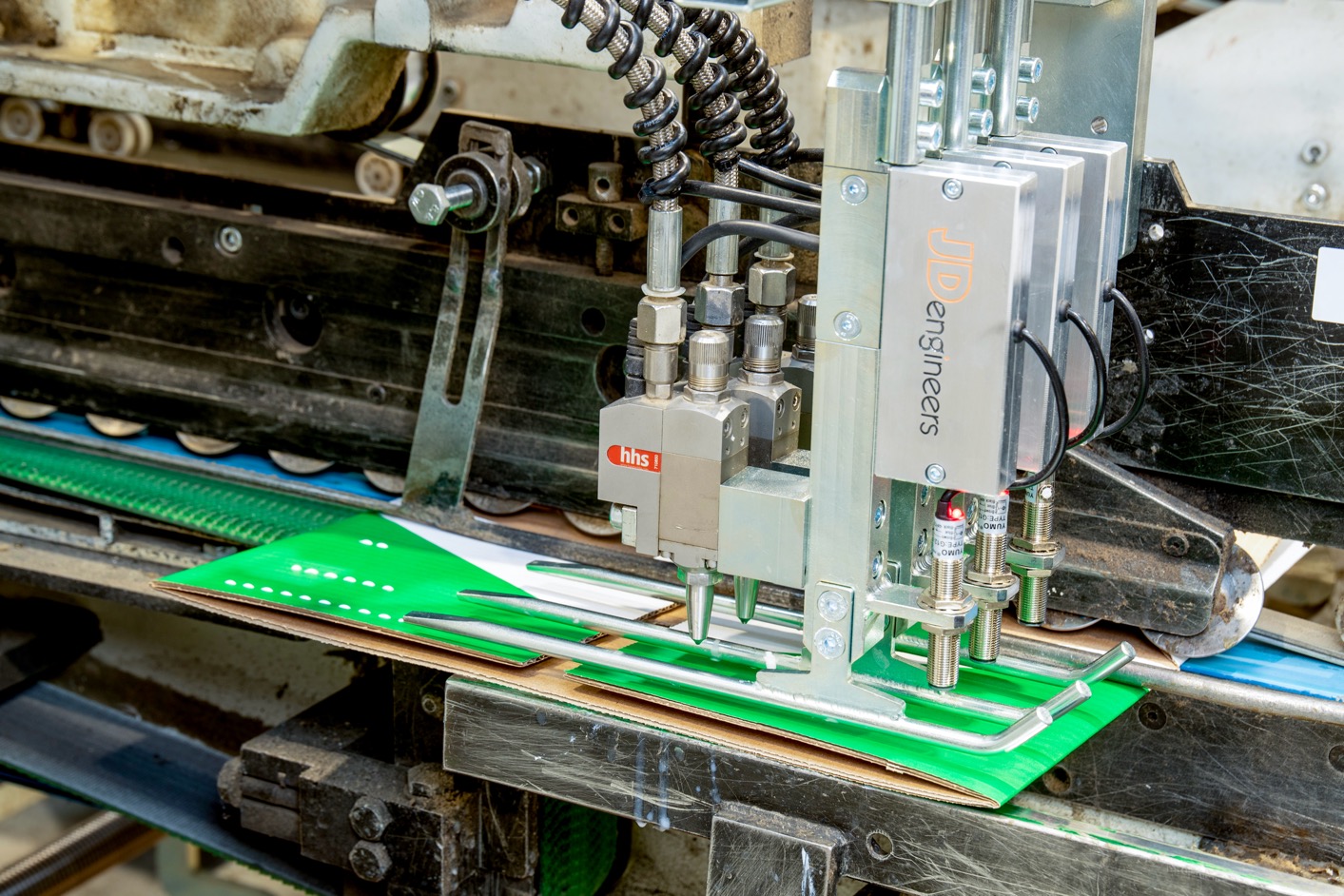

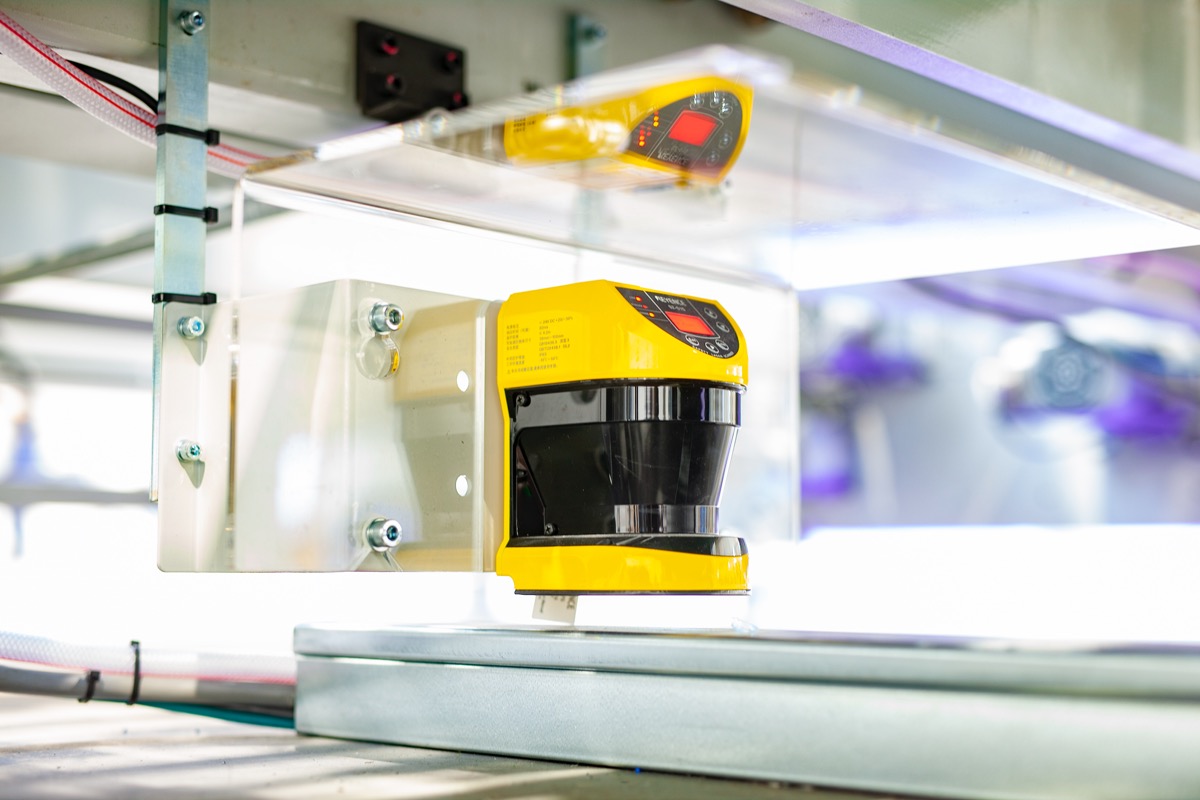

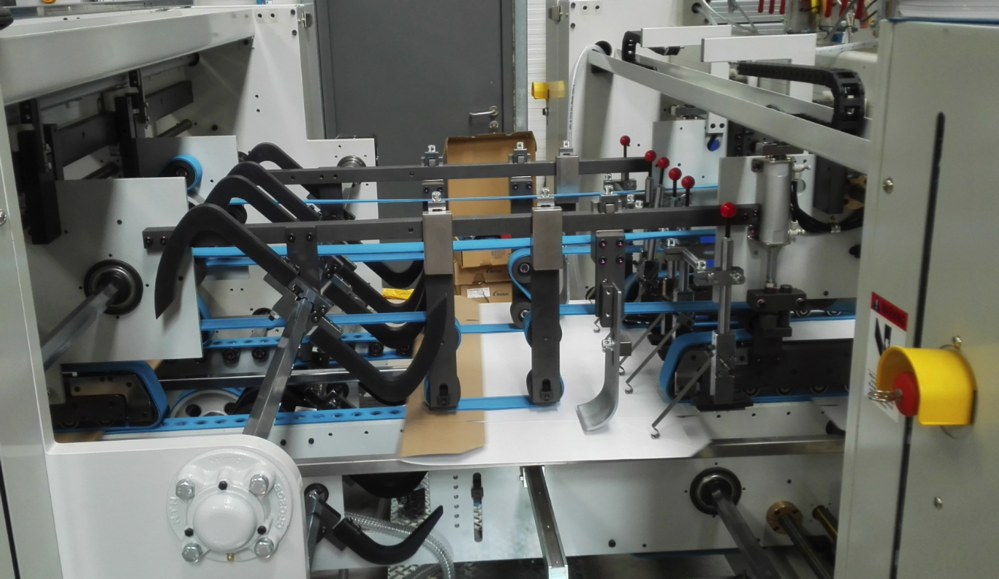

The Jam detection uses optical sensors to measure the length of the blank during production. In case an unacceptable difference is detected that could lead to damage, the machine will be (partly) switched off. Signal lights can be connected and a message, with time stamp, will be logged. Standard a total of 16 optical sensors and 16 signal lights can be connected to the system.

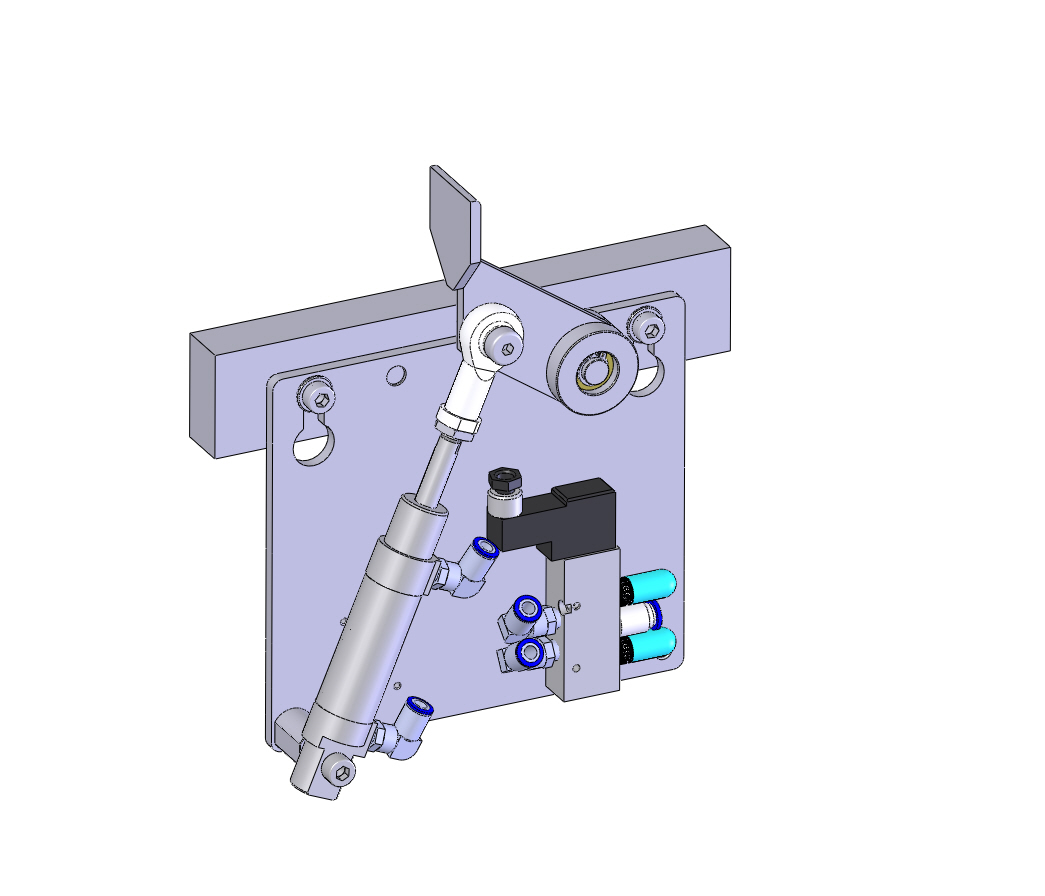

When a machine is equipped with an ejection unit an incorrect folded box will be ejected from the product flow.

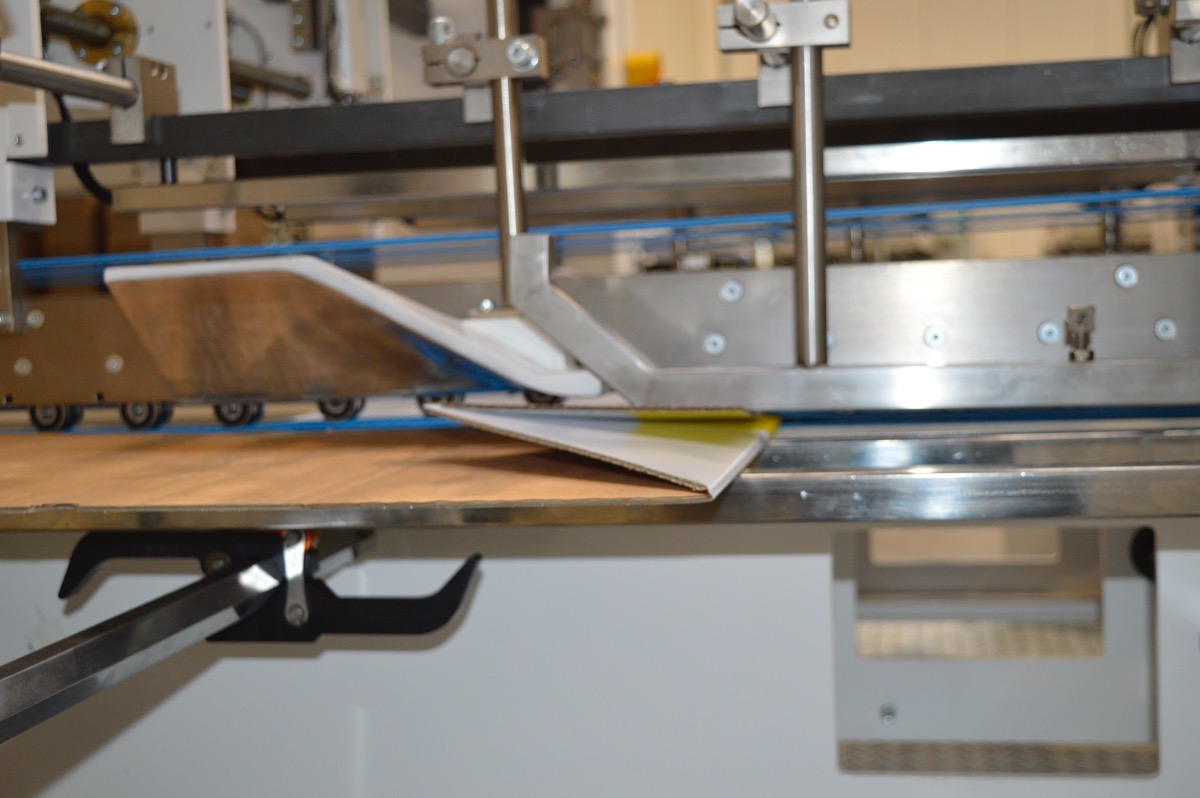

The detection sensors can be placed anywhere in the machine.