Specialty folder gluers for the cardboard industry

Sustainable folder gluer partner

JD Engineers B.V. is a specialized and innovative company that focuses on the production of high-quality folding and gluing machines for the corrugated board and cardboard industry. Our machines offer the possibility of automated folding and gluing of boxes in large volumes.

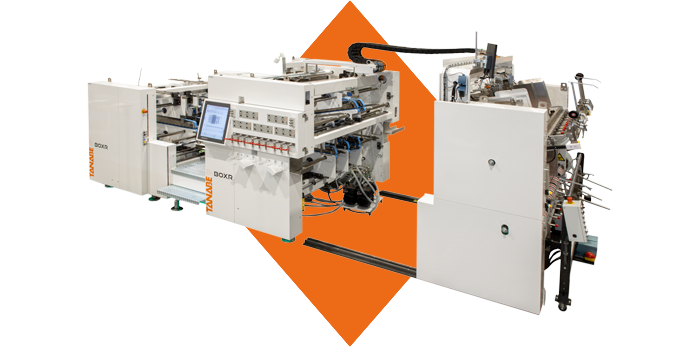

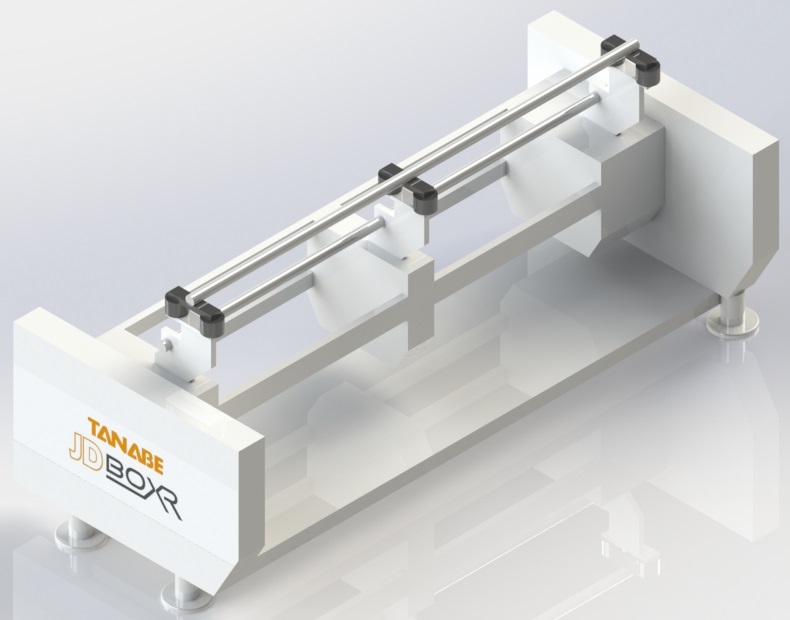

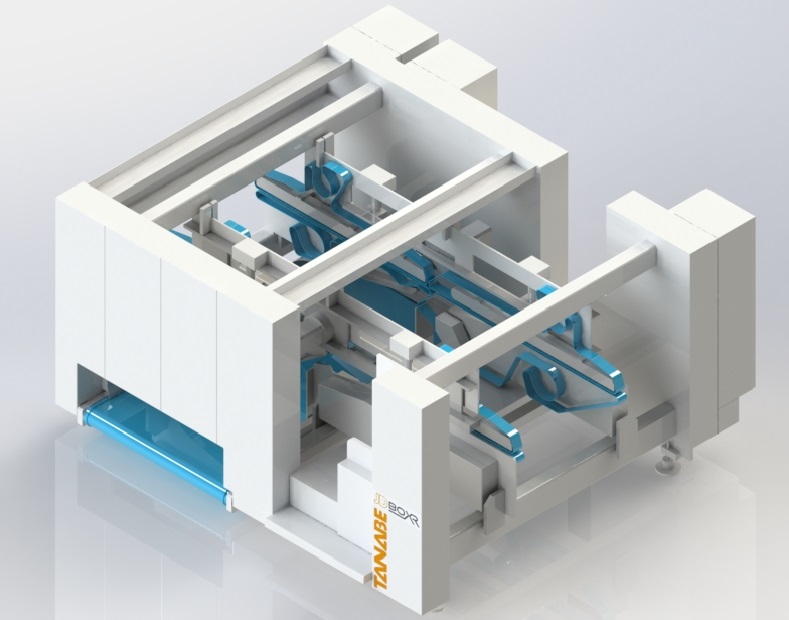

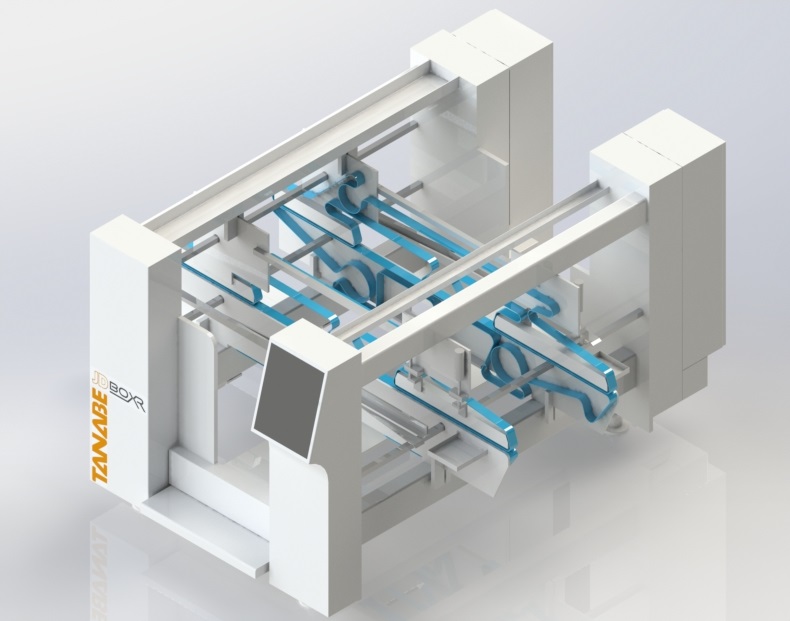

JD BOXR

Experience the very latest technology for folding boxes on a large scale with the Tanabe JD BOXR, a machine manufactured to perfection by JD Engineers in the Netherlands.

JD ERSX

Find out how JD Engineers’ Retrofit solutions can breathe new life into your existing machines, improve their durability and significantly reduce costs like maintenance, downtime, waste and energy consumption.

JD ERSX

Find out how JD Engineers’ Retrofit solutions can breathe new life into your existing machines, improve their durability and significantly reduce costs like maintenance, downtime, waste and energy consumption.

JD TWIN

The Tanabe JD-TWIN is a high-speed, precision gluing machine designed to glue blanks for applications such as shelf-ready packaging, inner partitions, and reinforcement

Wide range of options

JD Engineers’ specialty folder gluers are modular in design so that we can meet customer-specific requirements.

Retrofit – ERSX

The JD Engineers retrofit system offers a cost-effective, sustainable and performance-enhancing solution for companies that want to extend the life of their specialty folder gluers.

Some of the advantages:

Durability: extending the life of your machines.

Cost savings: a budget-friendly alternative to new machines.

Energy efficiency: reduced operating costs and environmental impact.

Improved performance: increase in productivity and quality.

Seamless integration: compatibility with modern technologies.

Specialty folder gluers for the corrugated and solid board industry

JD Engineers B.V. is a specialized and innovative company that focuses on the production of high-quality folding and gluing machines for the corrugated board and cardboard industry. Our machines offer the possibility of automated folding and gluing of boxes in large volumes.

With more than 40 employees, JD Engineers has become a leading player in the market. We have built a strong reputation for providing reliable machines and prompt service.

For example, we have developed the operating system for our machines in-house, including the JD BOXR, JD FUZR and JD TWIN. For older machines we have the upgrade kit JD ERSX for durability and more capacity.

Recycle

Avoid wasting equipment by replacing the (obsolete) controls.

Safe work environment

Safety light curtains, area scanners, up to date e-stop system and safe torque off motor drives for a safe work environment.

Automatic calculation

Automatic calculation of the transport positions, glue, backfold and other settings and store the perfect setting in the memory.

Safe with saving power

Excellent customer service

JD Engineers is committed to providing excellent customer service and support.

Downtime is expensive, so we work as fast and efficient as we can to get the machines back up and running as soon as possible.

To achieve this the JD Internet Service (JDIS) can be very helpful for troubleshooting. This is time saving and it even could save a technicians visit.

Support & service

When you choose JD Engineers for investing in new machines or for Retrofit services, you not only invest in an upgrade of your machines, but you also get access to their expert support and assistance.

JD Engineers’ team of skilled technicians will guide you through every step of the process, from initial assessment and consultation to installation, testing and ongoing maintenance.

Their commitment to exceptional customer service ensures you get the support you need to get the most out of your refurbished equipment.