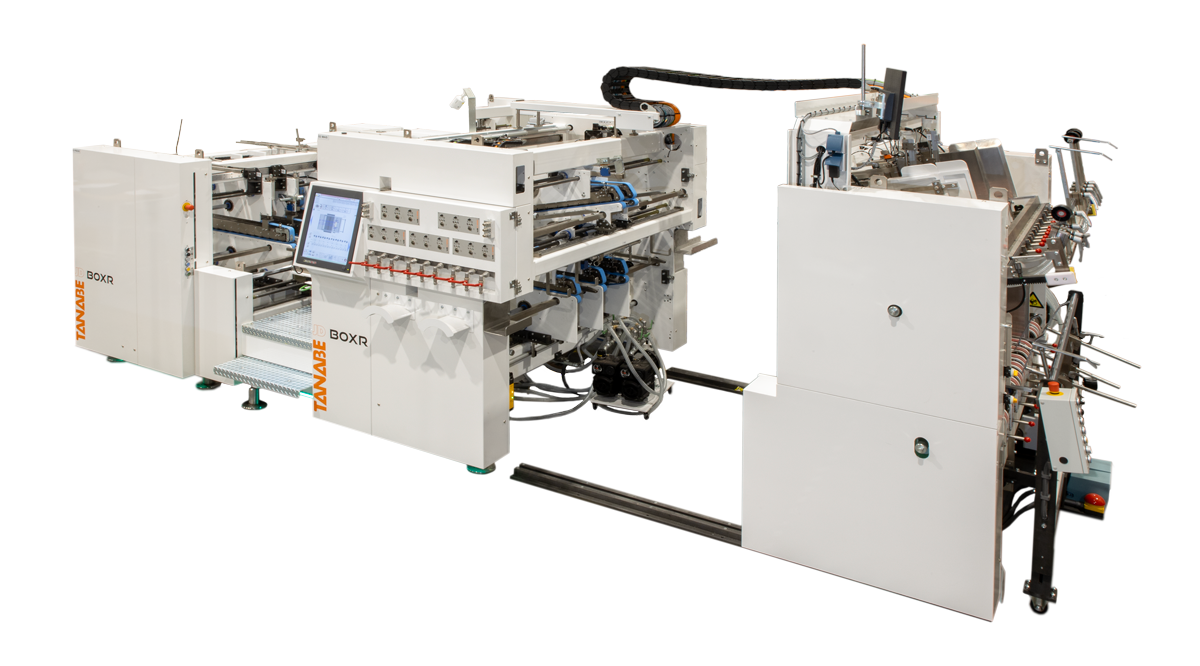

JD TWIN – The perfect solution for folding two pieces boxes

A machine manufactured to perfection by JD Engineers in the Netherlands.

The advantage of the Tanabe JD TWIN

The JD-TWIN is a high-speed, precision gluing machine designed to glue blanks for applications such as shelf-ready packaging, inner partitions, and reinforcement. It comes standard with the JD Special feed mode, allowing smooth handling of delicate and irregularly shaped blanks. Key features include easy accessibility, integrated glue control, availability in 1700 mm (67 inch) and 2400 mm (94 inch) widths, automatic frame adjustment, remote control, signal status light, and integrated glue detection for enhanced reliability and efficiency.

Additional the MAS function (Multi Aligning Section) can be used for high precision feeding. Press belts instead of press rollers prevent marking of delicate boxes.

Safe work environment:

Integrated safety light-curtains for optimal safe work environment

Buttons and E-stops:

Operator buttons and E-stops are always within reach

The perfect setting:

Automatic calculation of the order and store the perfect setting in the memory

Elevate your business with the Tanabe JD TWIN, a high-speed, precision gluing machine designed for folding two-piece boxes.

Don’t settle for less when it comes to folding and gluing two-piece boxes. Choose the Tanabe JD TWIN and experience the impact of state-of-the-art technology on your business. Contact us to learn more about how the Tanabe JD TWIN can add value to your production process.

The advantage of the Tanabe JD TWIN

The JD-TWIN is a high-speed, precision gluing machine designed to glue blanks for applications such as shelf-ready packaging, inner partitions, and reinforcement. It comes standard with the JD Special feed mode, allowing smooth handling of delicate and irregularly shaped blanks. Key features include easy accessibility, integrated glue control, availability in 1700 mm and 2400 mm widths, automatic frame adjustment, remote control, signal status light, and integrated glue detection for enhanced reliability and efficiency.

Additional the MAS function (Multi Aligning Section) can be used for high precision feeding. Press belts instead of press rollers prevent marking of delicate boxes.

Safe work environment:

Integrated safety light-curtains for optimal safe work environment

Buttons and E-stops:

Operator buttons and E-stops are always within reach

The perfect setting:

Automatic calculation of the order and store the perfect setting in the memory

Elevate your business with the Tanabe JD TWIN, a high-speed, precision gluing machine designed for folding two-piece boxes.

Don’t settle for less when it comes to folding and gluing two-piece boxes. Choose the Tanabe JD TWIN and experience the impact of state-of-the-art technology on your business. Contact us to learn more about how the Tanabe JD TWIN can add value to your production process.

| 1700 mm | 67 inch | 2400 mm | 94 inch | |

|---|---|---|---|---|

| Max. speed | 250 m/min | 820 ft/inch | 200 m/min | 656 ft/inch |

| Max. speed (MAS/Special feed/TWIN Feed) | 120 m/min | 394 ft/inch | 120 m/min | 394 ft/inch |

| Operator side | Left handed (optional: right handed) | |||

| Min. blank width upper blank | 530 mm | 21 inch | 530 mm | 21 inch |

| Max. blank width upper blank | 1650 mm | 65 inch | 2350 mm | 92 inch |

| Min. blank width lower blank | 530 mm | 21 inch | 530 mm | 21 inch |

| Max. blank width lower blank | 1700 mm | 67 inch | 2400 mm | 94 inch |

| Flute grades | A, B, C, E, F, BC, EB flute (1,5-6,6 mm / 0,06-0,26 inch) | |||

Recycle

Avoid wasting equipment by replacing the (obsolete) controls.

Safe work environment

Safety light curtains, area scanners, up to date e-stop system and safe torque off motor drives for a safe work environment.

Automatic calculation

Automatic calculation of the transport positions, glue, backfold and other settings and store the perfect setting in the memory.

Download brochure

Fill in your details below and receive the information brochure directly!

"*" indicates required fields