Discover refurbished folding-gluing machines from JD Engineers. Each machine has been fully overhauled and upgraded to meet exceptional levels of efficiency, durability, and accuracy.

Available soon:

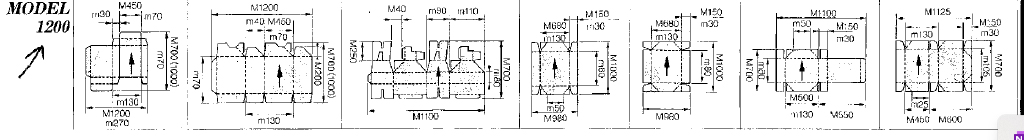

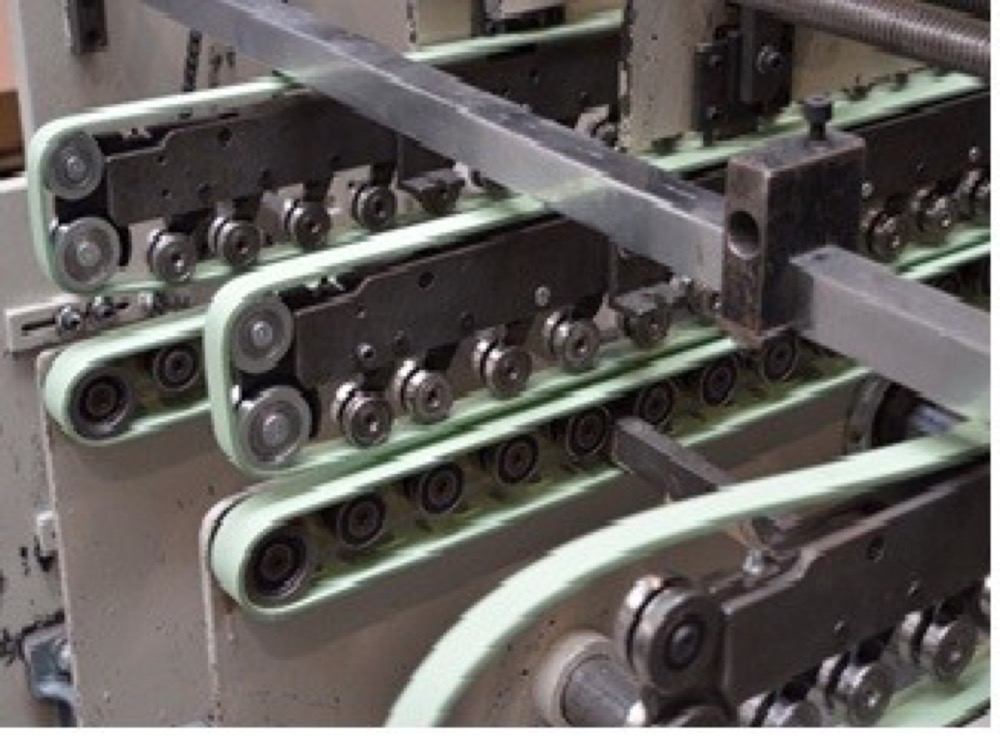

Tanabe 1200 JD ERSX. Look behind the scenes from an ERSX solution

We are proud to present a fully refurbished Tanabe folding-gluing machine with a working width of 1200 mm. This machine has been overhauled and upgraded, ensuring it meets the highest standards of performance and reliability.

Do you want more information or have a question?

We would be delighted to discuss this solution with you in more detail and answer any specific questions you may have. Our team is ready to support you with implementation, training, and long-term service to ensure you get the very best out of this upgraded Tanabe folding-gluing machine.

We are confident this investment will not only meet but exceed your production expectations. We look forward to the opportunity to work together.