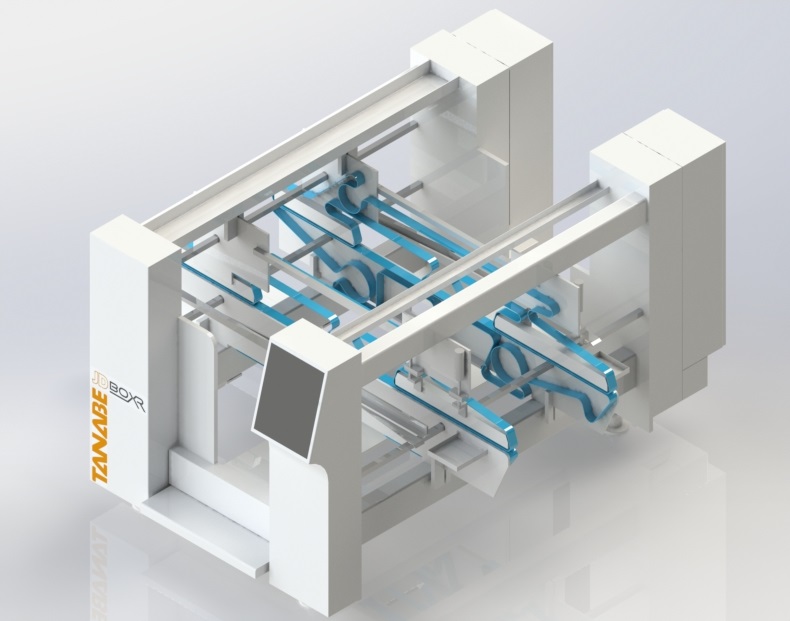

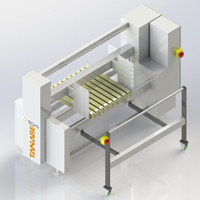

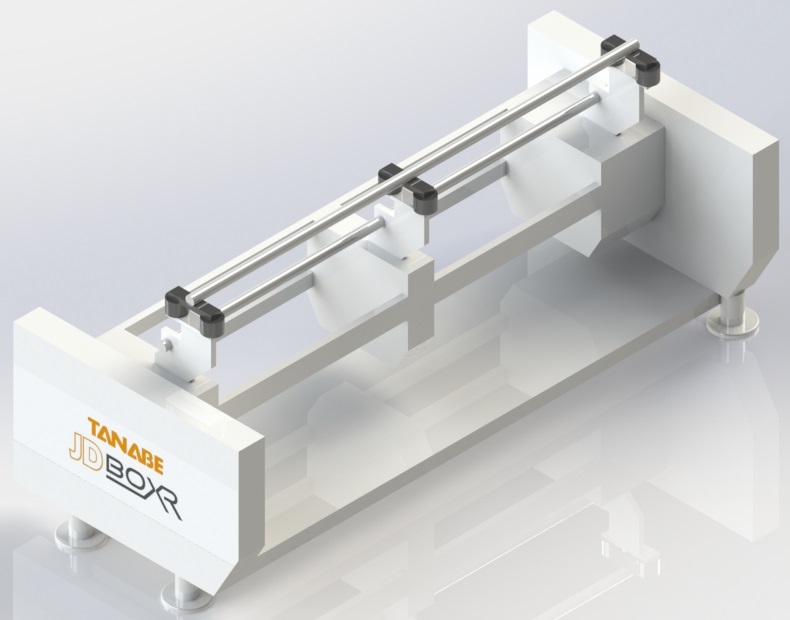

JD BOXR – Experience the very latest technology for folding corrugated and / or solid board boxes on a large scale

A machine manufactured to perfection by JD Engineers in the Netherlands.

The advantage of the Tanabe JD BOXR

Improved Efficiency:

With features such as the high-speed reject unit and the absolute measuring system, the Tanabe JD BOXR greatly improves the speed and accuracy of your folding and gluing processes.

Integrated quality control:

The integrated glue detection system and the length and diagonal check ensure that every box is checked.

Streamlined operations:

The user-friendly touch screen control system, LED status indication and open construction design simplify operation and maintenance, minimizing downtime and maximizing productivity.

Versatility:

The Tanabe JD BOXR is designed for a wide range of box types and sizes.

Reliable, Long Lasting Performance:

Manufactured with 25mm side frames and steel joints, the Tanabe JD BOXR has a stable construction that will stand the test of time, providing a reliable solution for folding and gluing boxes.

Customizable:

Due to its modular design, the Tanabe JD BOXR can be easily expanded with options to upgrade to additional touch screens and the versatile T-Unit or an ejection unit to meet your unique box folding needs.

Take your business to the next level by investing in the Tanabe JD BOXR specialty folder gluer. Experience the benefits of advanced technology, unparalleled efficiency and extensive quality control in various sections.

Don’t settle for less than the best when it comes to folding and gluing boxes. Choose the Tanabe JD BOXR and discover the difference state-of-the-art technology can make for your business. Contact us to learn more about how the Tanabe JD BOXR can add value to your production process.

The advantage of the Tanabe JD BOXR

Improved Efficiency:

With features such as the high-speed reject unit and the absolute measuring system, the Tanabe JD BOXR greatly improves the speed and accuracy of your folding and gluing processes.

Integrated quality control:

The integrated glue detection system and the length and diagonal check ensure that every box is checked.

Streamlined operations:

The user-friendly touch screen control system, LED status indication and open construction design simplify operation and maintenance, minimizing downtime and maximizing productivity.

Versatility:

The Tanabe JD BOXR is designed for a wide range of box types and sizes.

Reliable, Long Lasting Performance:

Manufactured with 25mm side frames and steel joints, the Tanabe JD BOXR has a stable construction that will stand the test of time, providing a reliable solution for folding and gluing boxes.

Customizable:

Due to its modular design, the Tanabe JD BOXR can be easily expanded with options to upgrade to additional touch screens and the versatile T-Unit or an ejection unit to meet your unique box folding needs.

Take your business to the next level by investing in the Tanabe JD BOXR specialty folder gluer. Experience the benefits of advanced technology, unparalleled efficiency and extensive quality control in various sections.

Don’t settle for less than the best when it comes to folding and gluing boxes. Choose the Tanabe JD BOXR and discover the difference state-of-the-art technology can make for your business. Contact us to learn more about how the Tanabe JD BOXR can add value to your production process.

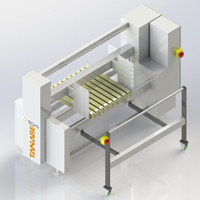

Feeder section

The JD FEEDER is a servo driven feeder with a single feed function as a standard. Equipped with vacuum belts and pneumatic feedgates as helpfull it ensures a perfect infeed of the specialty folder gluer. A special feeder is developed for robot feeding. Basically the JD ENGINEERS feeders can be mounted to other brands of folder gluers as well as a retrofit. The optional JD special feed will align “angled” boxes by using servo technology.

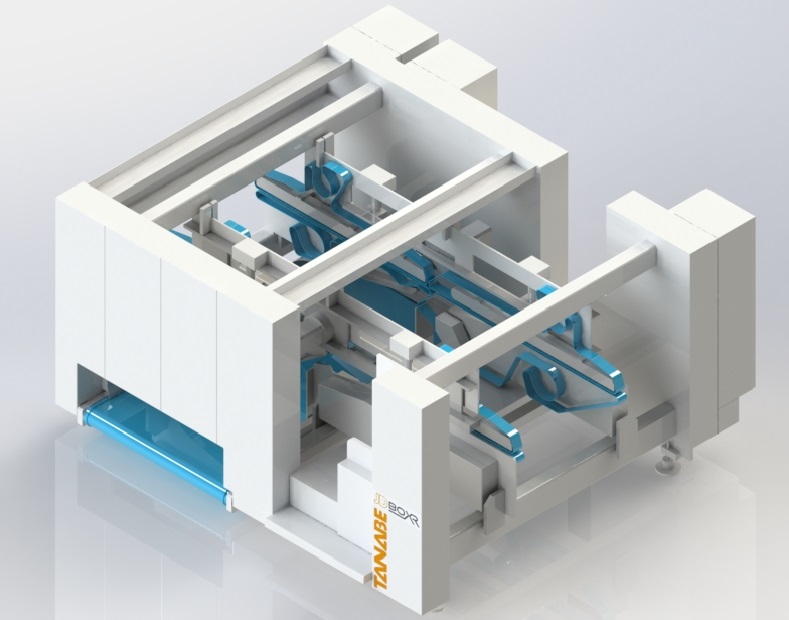

First folding unit

- Independent servomotor drive

- Auto set. Calculated by JD box editor

- 2 servo driven top and bottom belts

- Pneumatiatic movement up/down upper carriers

- Touch screen (HMI, on operator side)

- Pneumatic movement up/down front fold hooks

- Electronic Jam-stop

- Servo driven backfold incl. 2 sizes quick lock folding hooks

- Servo driven front folding incl. quick lock folding hooks

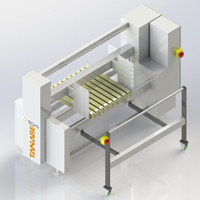

Second folding unit

- Independent servomotor drive

- Auto set. Calculated by JD box editor

- 3 servo driven top and bottom belts

- Pneumatiatic movement up/down upper carriers

- Touch screen (HMI, on operator side)

- Pneumatic movement up/down front fold hooks

- Electronic Jam-stop

- Servo driven backfold incl. 2 sizes quick lock folding hooks

- Servo driven front folding incl. quick lock folding hooks

Final fold unit

- HMI Touch screen

- Safety area scanner

- Glue bridge with connectors for 12 glue guns

- JD glue control suitable to connect different brands of guns / pump / detection systems

- Adjustable press rolls

- “Flip up” middle upper carrier

- Posibillity for “short” folding belt

- (diagonal) folding detection

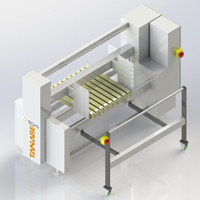

Trombone unit

- Servo driven upper and lower belts

- Height adjustable upper belts

- Pneumatic batch counting by kicker / sprayer

- Servo driven rotary stopper

- Spanker (batch height controlled by sensor)

- Waste reducer

- HMI Touch screen

Press conveyor

- Servo driven

- Adjustable in all directions by motor

- Pneumatic pressure setting with memory function

- Max length of box is 1600 mm.

- Take off table

- UV black light

- Squaring plate (with or without LSU units).

- Massive top belt (sponge belt is an option)

| BOXR 1250 | BOXR 1450 | BOXR 1700(1450) | BOXR 1700 | BOXR 2400 | BOXR 2800 | BOXR 3200 | ||

|---|---|---|---|---|---|---|---|---|

| min | min | min | min | min | min | min | ||

| Straight line WxL | min | 130×70 | 155×100 | 155×160 | 185×160 | 250×160 | 250×160 | 250×160 |

| max | 1250×1000 | 1450×1500 | 1700×1800 | 1700×1800 | 2400×1800 | 2800×1800 | 3200×1800 | |

| Crash lock WxL | min | 130×70 | 155×100 | 155×160 | 185×160 | 250×160 | 250×160 | 250×160 |

| max | 1250×1000 | 1450×1500 | 1700×1800 | 1700×1800 | 2400×1800 | 2800×1800 | 3200×1800 | |

| 4-corner WxL | min | 130×140 | 155×100 | 155×150 | 185×150 | 250×240 | 250×240 | 250×240 |

| max | 980×1000 | 1300×1500 | 1500×1800 | 1500×1800 | 1680×1800 | 2080×1800 | 2080×1800 |

* Dimensions: mm

** Subject to flap ratio

Board materials that the Tanabe JD BOXR equipment is capable of handling:

Solid board:

- 250 – 800 g/m2, maximum thickness: 2 mm (for type: 1250 wide)

- 250 – 2000 g/m2, maximum thickness: 2 mm (for type: 1700 and wider)

Corrugated board:

- C, B, E, F, N flute (for type: 1250 wide)

- A, C, B, E, F, N, BC, BE, EE flute (for type: 1450 and wider)

- Length control on all sensors (jam detect)

- Optional: Diagonal folding control

- Optional: Self-learning glue detection (integrated in JD Glue control)

- Optional: Barcode scanner (presence and readability)

- Optional: Gap control by camera

Transform your folding and gluing processes today

Take your business to the next level by investing in the Tanabe JD BOXR specialty folder gluer. Experience the benefits of advanced technology, unparalleled efficiency and extensive quality control in various sections.

Don’t settle for less than the best when it comes to folding and gluing boxes. Choose the Tanabe JD BOXR and discover the difference state-of-the-art technology can make for your business. Contact us to learn more about how the Tanabe JD BOXR can add value to your production process.

BOX SUPPORT

The JD Box Support is special designed for easy robot feeding. The sideguides will move to the outside when the robot is dropping a new load of blanks. The downforce feedgates with super grip belts will take care of a perfect infeed of the blanks. A vibration motor is also a very useful tool for a smooth infeed.

JD E-unit

Thanks to the integration with the glue detection, diagonal folding and length control systems, the super-fast discharge ejection unit section can handle speeds of up to 60,000 pieces per hour. As a result, a manual check is no longer necessary and the batch counting will always be correct.

JD PRESS SECTION

In combination with a T-unit or when hotmelt is used to close the boxes an extra set of press rollers is recommended for a better tag of the glue directly after the section where the glue is added. It can be a direct drive or a belt drive section with a double set of press rolls depending on the customer’s needs.

Recycle

Avoid wasting equipment by replacing the (obsolete) controls.

Safe work environment

Safety light curtains, area scanners, up to date e-stop system and safe torque off motor drives for a safe work environment.

Automatic calculation

Automatic calculation of the transport positions, glue, backfold and other settings and store the perfect setting in the memory.

Download brochure

Fill in your details below and receive the information brochure directly!

"*" indicates required fields